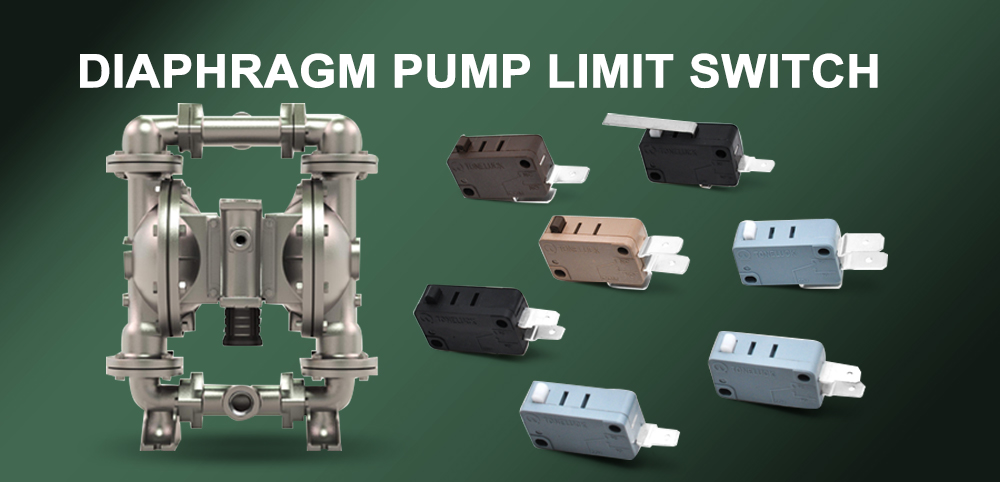

Application of Diaphragm Pump in L Series Limit Switch

A diaphragm pump is a commonly used industrial pump. Its main feature is that it can completely isolate the conveying medium from the pump body, so as to realize pollution-free and leak-free conveying. In the application of the L series limit switch, the diaphragm pump plays an important role. The equipment sensitivity of the L series micro switch is extremely high, which can sense the change of the medium in the pump and other problems on the production line in real-time, and adjust and eliminate them in time.

1. Features and application scenarios of L series limit switches

L series limit switch is a common electromechanical switch device, which is widely used in industrial automation control systems. Its main feature is that it has the advantages of sensitive contact, reliability, and stability, and convenient installation and use. In industrial production, L series micro switches are often used in detection, sensing, control, and other aspects. At the same time, L series micro switches can also be customized according to different specifications and models to meet the needs of different industries.

2. Introduction of diaphragm pump

The diaphragm pump is a widely used pump equipment, mainly used to transport some special media or occasions with high requirements on the media. The main structure of the diaphragm pump is a diaphragm composed of two pump bodies and a flat elastic material. The driving device makes the diaphragm reciprocate, forming a series of working gaps, and sucking and discharging the medium. Diaphragm pumps can not only pump liquids but also convey viscous, corrosive, or high particle-content media. Its characteristic is that it is not easy to leak, and the pump is completely isolated from the medium, achieving the effect of no pollution.

3. Guaranteed safe use of L series limit switches

The L series micro switch has high contact sensitivity and reliability. Through the probe installed above the diaphragm pump, it can sense the medium condition in the pump body with high precision. Once the medium is abnormal, the L series micro switch can immediately send a signal to remind the operator to take corresponding measures in time to avoid unnecessary losses and ensure the normal operation of the production line.

The combination of a diaphragm pump and an L series micro switch can improve the safety and stability of the pump. The diaphragm material in the diaphragm pump is usually a hydraulic diaphragm or a pneumatic diaphragm, which has good elasticity and wear resistance. When the medium has a high viscosity and a large number of particles, the diaphragm pump can still work normally without being affected. At the same time, the L series micro switch can also monitor important parameters such as temperature and pressure inside the pump body in real-time, and adjust them according to the actual situation. This double guarantee can greatly improve the safety and stability of the diaphragm pump and reduce safety risks in the production process.